Offer

Our offer includes open-cell sound absorbing materials and closed-cell CFT foil, which is designed to disperse sound. There is a possibility of joining together and laminating raw materials with aluminum and PVC films or a rock. Below are some examples of our solutions:

Soundproofing of boats and yachts:

1. ALU and ALU-Z series PR foam is a flame retardant flexible polyurethane foam. It is produced using recycled organic materials. The product is available in the form of boards, mats and in customised shapes. PonSil PR is recommended for use in the automotive, shipbuilding and construction industry. The foam is used as acoustic and thermal insulation. Moreover, it protects insulated items against mechanical damage. The product is also available in a self-adhesive version.

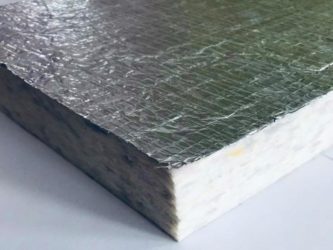

2. PonSil Noise Reducer ALU is a composite material with high sound-absorption properties. It has been designed to provide total noise control. It consists of three components: two layers of non-flammable polyurethane foam which absorb sound and provide thermal insulation, and a flexible CFT film located between the layers to keep sound within the composite. The entire product is coated with a metallised fabric with high temperature resistance (600°C) and high resistance to mechanical damage. PonSil NOISE REDUCER ALU solves the problems of temperature control and noise in the insulated object.

3. PonSil NBR is a flexible, elastomeric insulation material with a closed cell structure, which prevents condensation and reduces heat loss. The closed cell structure acts as a permanent vapor barrier, stops effectively vapor permeability and thus ensures reliable insulation throughout the system’s lifetime. The foam is a self-extinguishing material, not spreading fire, not creating burning drops. Thanks to its noise-reducing properties, as well as a structure free of dust and fibers, it is suitable for use in construction and cars.

Product Advantages:

- Closed cell structure resistant to water vapor diffusion.

- Corrosion resistant.

- Very good thermal parameters minimize energy losses.

- Flexible, not dusty, leaving no fibers.

- Antimicrobial protection.

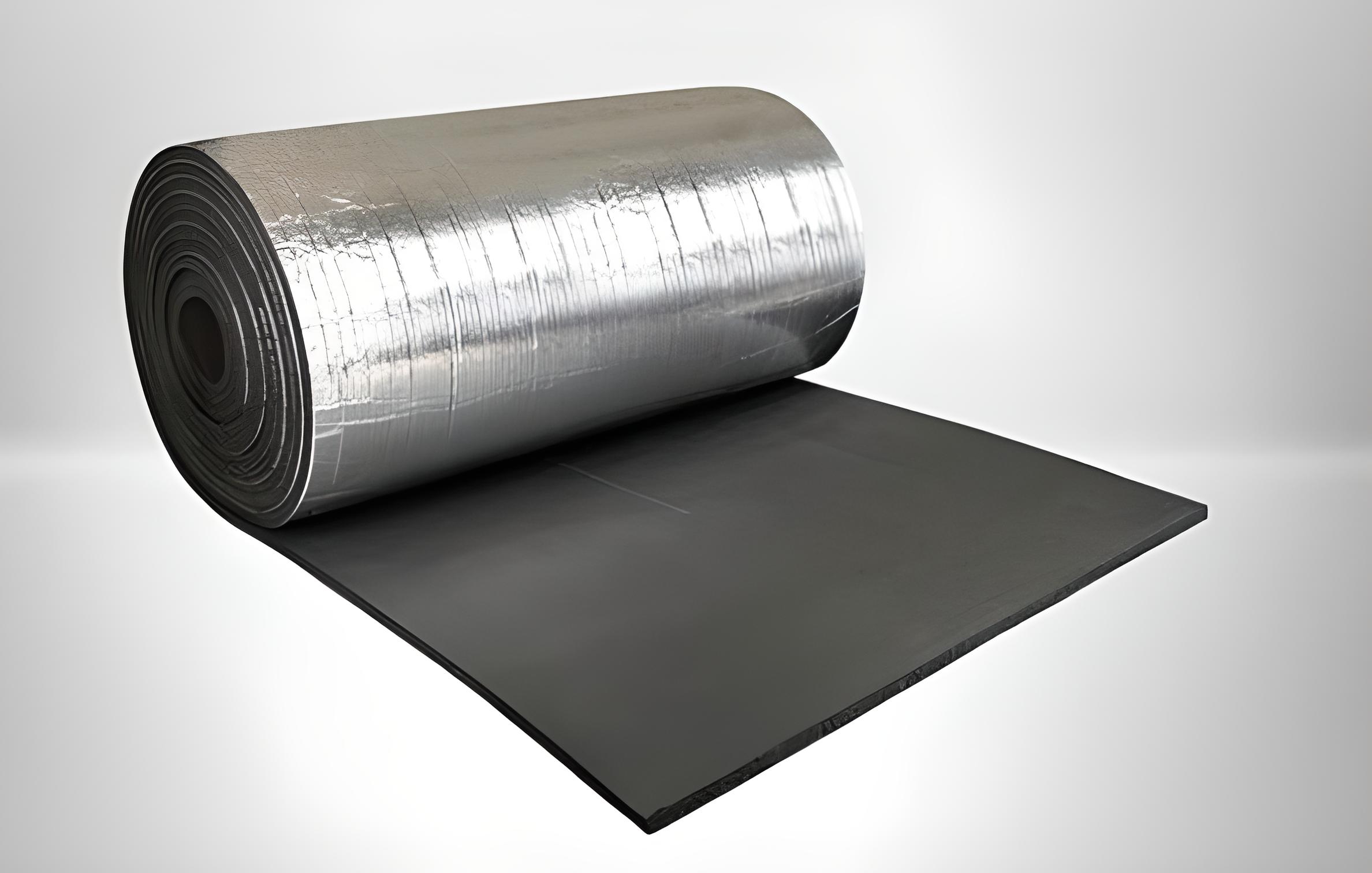

4. PonSil NBR ALU is a flexible insulation material with a closed cell structure that prevents condensation, reduces heat loss and improves acoustic comfort. The closed cell structure acts as a permanent vapor barrier, effectively stops vapor permeability, and thus provides reliable insulation throughout the life of the system. The foam has an aluminum coating that is easy to maintain. Thanks to the aluminum coating, the product has increased thermal resistance and is resistant to UV radiation.

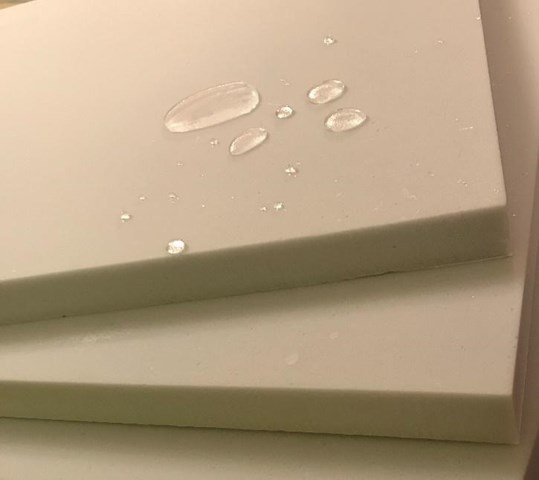

5. Hydro PonSil is a foam based on melamine resin. The foam has an open cell structure, which provides special properties useful for thermal and acoustic insulation. Through a process of hydrophobisation process, the foam repels water molecules, so it may be used in areas exposed to fluids and damp. The main advantages of this material include its high ability to absorb sound (up to 90 %), especially medium and high frequencies, while maintaining a very low weight (only 9 kg/m³). In addition, the foam has an exceptionally low coefficient of heat conductivity (0.035 W/mK at 10°C), making it suitable for thermal insulation and significantly reducing heat loss. These properties allow the user to control both noise and temperature, increasing comfort in insulated areas. The foam is flexible, which makes its use much easier. The product can also be easily cut to the required size. The foam has a non-combustibility certificate, DIN 4102 in Class B. Standard DIN 4102 refers to fire classification standards and in relation to EN 13501-1, the degree of smoke emission has been classified as s2 with no flaming droplets (d0). These properties make the foam a modern and multi-functional solution for problems with thermal and acoustic insulation. The foam is available in two versions: self-adhesive and with an aluminium foil facing.

6. Melamine foam (Basotect G+) is based on melamine resin. The foam has an open cell structure which provides special properties useful for thermal and acoustic insulation. The main advantages of this material include its high ability to absorb sound (up to 90 %), especially medium and high frequencies, while maintaining a very low weight (only 9 kg/m³). This makes the material perfect for acoustic insulation of buildings and means of transport, machines, ventilation devices, etc.

The product is available in the form of 2100×1250 and 2500×1250 boards with thickness ranging from 5mm to 250mm.

7. PonSil FIBER is a material made of polyester resins, reinforced inside with glass fibre. It is resistant to weathering, UV radiation, ageing, industrial flue gases and the aggressive maritime climate. The open cell structure of the fibres ensures very good sound absorption. PonSil FIBER is also available as a self-adhesive, hydrophobic and oleophobic product.

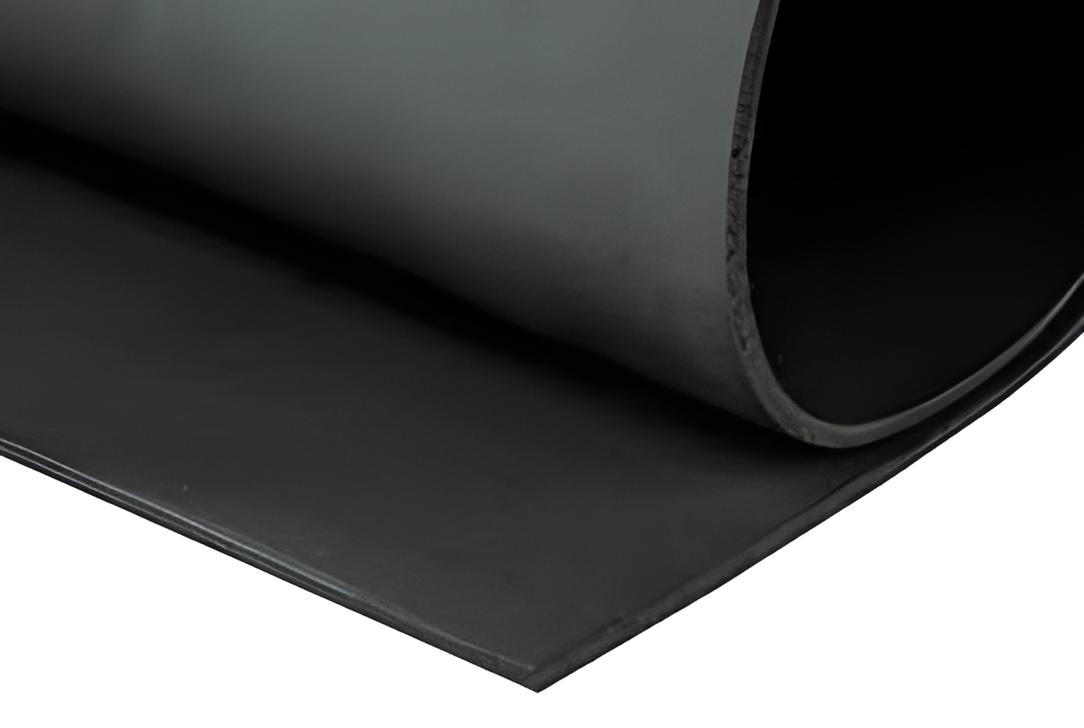

8. PonSil NBR/PCV foam is an insulating material that can be used as a pad or underlay for fuel tanks. The use of PonSil NBR/PCV foam as a substrate for fuel tanks can have several purposes:

- Thermal insulation: PonSil foam can help with thermal insulation, which can be especially important for fuel tanks. Thermal insulation can help keep the fuel temperature within the proper range, which can make a difference to fuel efficiency and quality.

- Corrosion Protection: Fuel tanks are at risk of corrosion from fuel, moisture and other factors. PonSil foam can act as a barrier, protecting the metal surface of the tank from direct contact with elements that can accelerate the corrosion process.

- Vibration and Shock Reduction: Placing foam under the fuel tank can help reduce vibrations and shocks that may occur when using a vehicle or device. This can contribute to improving the durability of the tank itself and the comfort of use.

- Protection against mechanical damage: The foam can also act as a protective layer against mechanical damage, such as scratches, impacts or abrasions, which can occur on the surface of the fuel tank.

- Sealing: The foam can act as a sealing element, helping to minimize the risk of fuel or vapor leaks

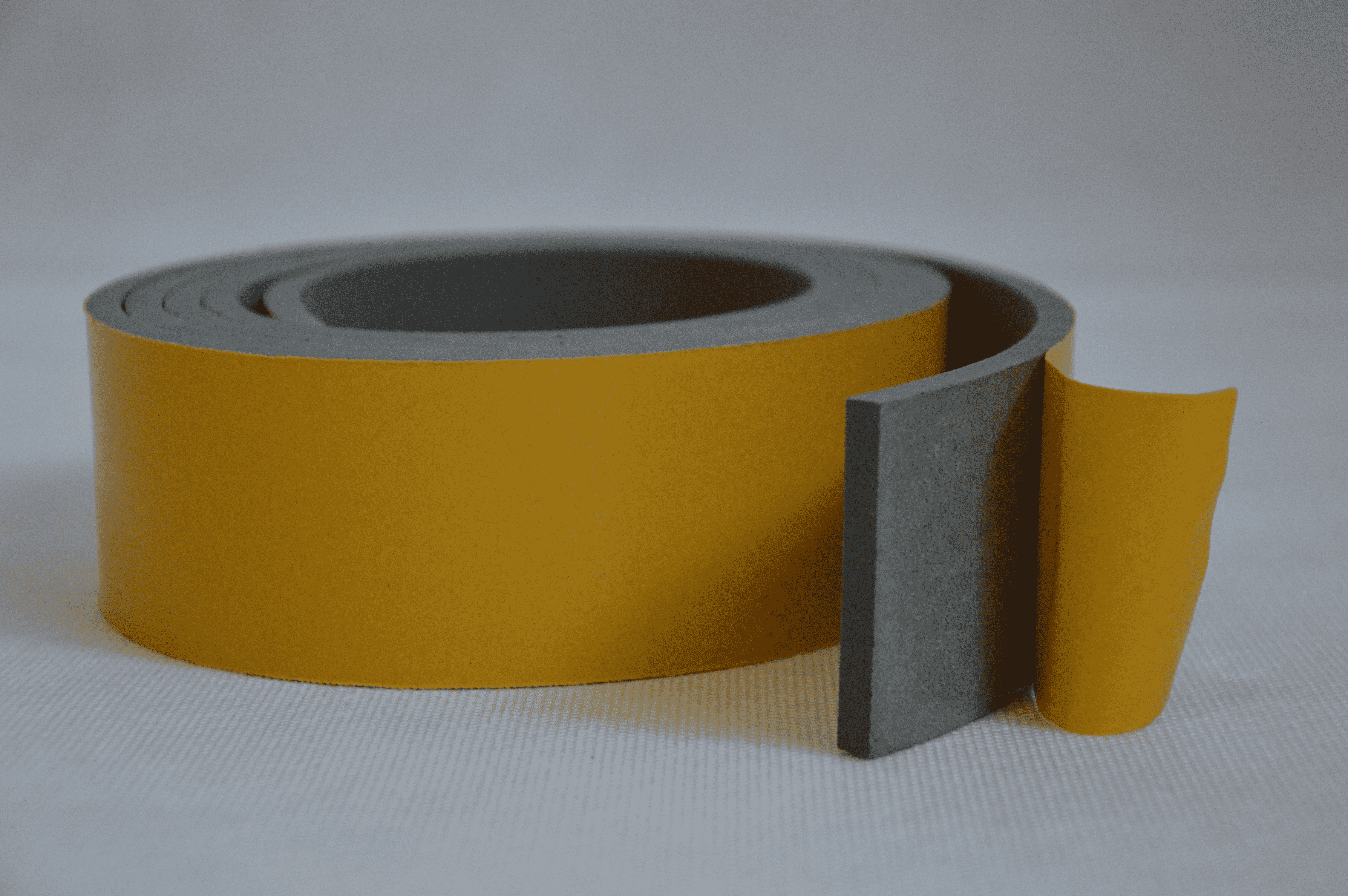

9. PonSil EPDM are a commonly used type of insulation in a variety of industries and applications. EPDM is an elastomer with good resistance properties to many factors, such as temperature changes, ozone, UV radiation and many chemicals. Here is some information about EPDM gaskets:

- Weatherability: EPDM is known for its exceptional weatherability, including UV and ozone resistance. Therefore, EPDM gaskets are often used outside buildings, in roofing systems, windows, doors, etc.

- Temperature resistance: EPDM gaskets are flexible over a wide temperature range, which means they retain their elastic properties at both low and high temperatures.

- Insulation: Due to its flexible and weather-resistant properties, PonSil EPDM is often used to insulate various components such as windows, doors, pipes and ventilation systems.

- Tensile and tear resistance: EPDM has good mechanical properties, including tensile and tear strength, making it an effective material for gaskets that need to be flexible but also durable.

- Industrial applications: EPDM is also used in the automotive industry, in hydraulic systems, as shock-absorbing elements in machines and devices, and in the food industry as a material that does not interact with food.

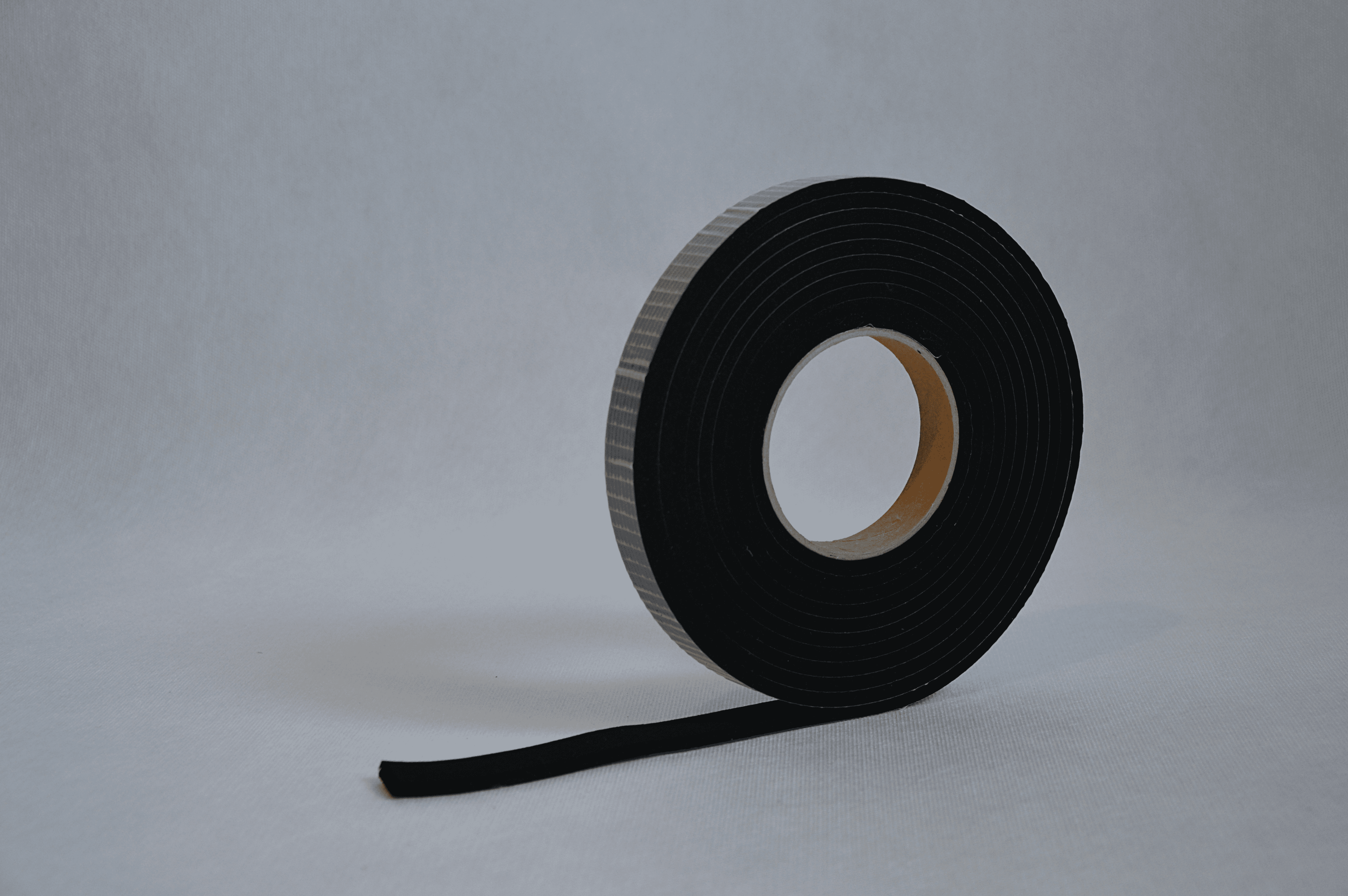

10. PonSil PE is a type of foam made of polyethylene (PE) – a thermoplastic material that is widely used in various fields due to its mechanical, chemical and thermal properties. Polyethylene is a material that is both lightweight and durable. PE foam retains these properties, making it an attractive option for applications where it is important to achieve strength with minimal weight. PE foam has insulating properties that can be used for thermal insulation of various elements, such as pipes, walls, roofs or floors. It can help maintain temperature and prevent heat loss. PonSil PE is water and moisture resistant, making PE foam suitable for applications where moisture protection is needed, such as construction and packaging. PonSil PE can act as a sound deadening layer, which is useful in applications where noise or vibration reduction is required.